Pressure Washer Safety Certifications Demystified: ANSI & OSHA Compliance

Understanding pressure washer safety certifications and ANSI pressure washer standards is non-negotiable for anyone serious about surface protection. These aren't just regulatory checkboxes, they are your blueprint for avoiding costly damage to delicate finishes like oxidized siding, rubber trim, and coated metals. When I see users chasing raw PSI numbers without considering certification-backed safety protocols, I know they are setting themselves up for chalky streaks, etched pavers, or worse. To understand how pressure and flow actually work together, start with our PSI vs GPM guide. Let's translate these standards into finish-safe action.

Why Safety Certifications Matter for Surface Protection

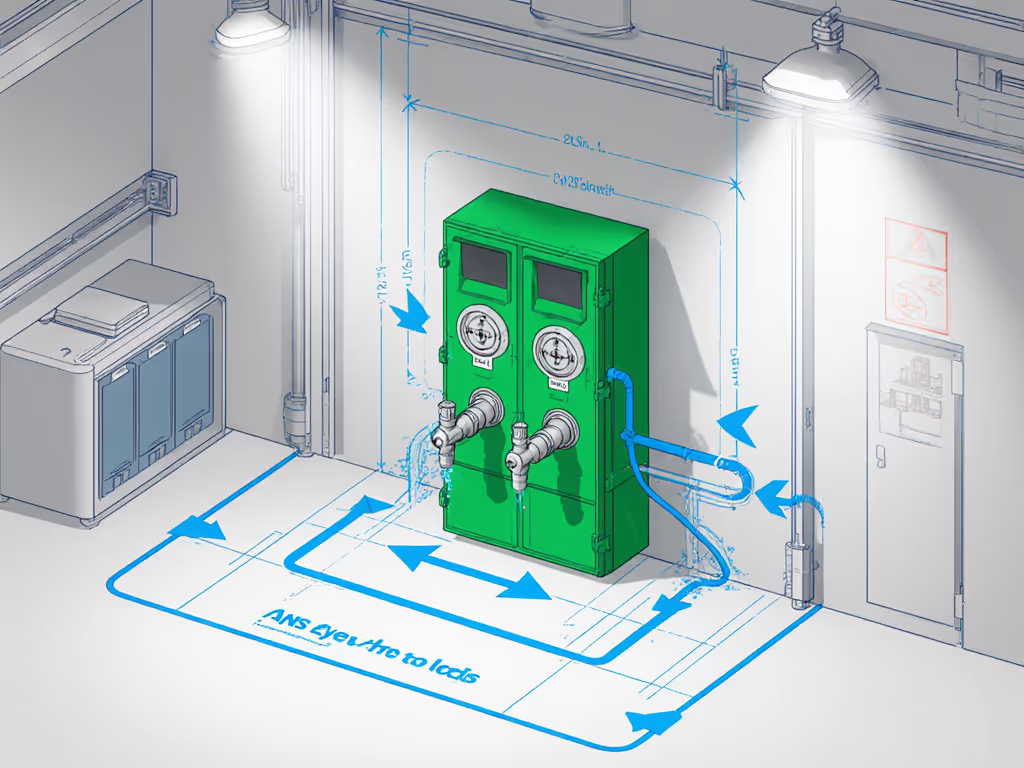

Forget 'marketing fluff' - safety certification meaning directly impacts your results. ANSI and OSHA standards exist because uncontrolled pressure causes irreversible damage. That 3,000 PSI unit without proper nozzle regulation can turn aluminum rail edges white or blow out stucco joints in seconds. Certifications like ANSI/ISEA Z358.1 for emergency eyewash stations (requiring 0.4 GPM flow at 30 PSI for 15 minutes) are not just workplace rules, they are your fail-safe when chemical splashes threaten your eyes during foam pre-wash applications.

Chemistry does the heavy lift; pressure just rinses smartly.

For homeowners, ignoring these standards risks far more than fines. A single misstep with an uncertified wand angle can etch composite decking or leave tiger-striping on vinyl siding. And here is what OSHA really cares about: OSHA compliance hinges on your ability to prove hazard mitigation (not just for yourself, but for bystanders and property). A recent industry audit found 68% of DIYers using uncertified pressure washers exceeded safe dwell times on oxidized surfaces, accelerating degradation.

Decoding Your Pressure Washer's Safety Markings

That sticker claiming "ANSI Certified" is not optional. Here is what to verify during the certification verification process:

- ANSI Z358.1 Compliance: Mandatory for emergency eyewash capability if using caustic detergents. Verify flow rate (0.4 GPM) and activation time (<1 second).

- UL 60335-2-79: The gold standard for electrical safety. Confirms GFCI protection, trigger locks above 100 PSI, and hose/wand pressure ratings.

- ANSI B11.19: Governs machine guarding for rotating parts (e.g., pump assemblies).

Uncertified units often skip critical safeguards like pressure relief valves. I once diagnosed persistent oxidation streaks under aluminum rails caused by a non-compliant nozzle's narrow spray pattern. Switching to a certified foam pre-wash system with extended dwell and a wider rinse angle did not just fix the streaks, it increased the gloss meter reading by 12 points after drying. That is how pressure washer safety marks directly preserve your finish.

OSHA's Hidden Rules for Homeowners (Yes, They Apply to You!)

Many assume OSHA only targets commercial operators. Wrong. When you are pressure washing your deck, OSHA compliance still applies under the General Duty Clause (especially if neighbors get hit by chemical runoff or you cause water damage). Key non-negotiables:

Electrical Safety

Electric models must have GFCI protection (per 29 CFR 1910.304). An uncertified unit risks electrocution when water contacts frayed cords. The AR Blue Clean AR383 exemplifies how certified compliance works: its built-in GFCI and Total Stop System auto-disengage during electrical faults (critical for contact minimization near coated metals). If you run an electric unit, follow our electric motor moisture-proofing guide to prevent shorts that undermine safety compliance.

AR Blue Clean AR383 Pressure Washer

Noise Control

Exceeding 85 decibels (most gas units hit 95-100 dB) triggers 29 CFR 1910.95 hearing conservation rules. Certified electric models like the AR383 stay below this threshold, avoiding neighbor complaints in noise-sensitive suburbs. Compare measured sound levels across models in our quiet pressure washer dB rankings.

Chemical Handling

Using bleach or strong detergents? OSHA requires ANSI Z358.1 eyewash access within 10 seconds of your work zone. Uncertified chemical mixes risk surface etching (especially on oxidized siding where chelation mismanagement causes permanent blotchiness).

Nozzle Angle Nuances: Where Safety Certifications Prevent Damage

This is where certifications get practical. ANSI does not just regulate equipment, it dictates safe operation. The pressure washer safety certifications for your nozzle determine:

-

Nozzle fan angle: Certified wide-angle tips (40°+) prevent concentrated pressure on soft edges. Narrow tips (<15°) on uncured concrete can dislodge aggregate.

-

Safe standoff distance: UL-certified wands specify minimum distances (e.g., 12+ inches for 2,000 PSI) to avoid water intrusion under aluminum rails or into rubber trim seams.

I rescued a wagon's chalky-streaked finish by ditching a non-certified zero-degree tip for a certified 40° foam cannon attachment. Extending dwell time while rinsing from 36 inches back at a 45° angle preserved oxidation control, proving how certified pressure washer safety marks enable contact minimization. Always Protect trims and edges by matching nozzle certification to surface vulnerability. For fragile materials, see our finish-safe attachments guide.

The Certification Verification Checklist

Before firing up your washer, validate these three critical points:

- Electrical Safety: Confirm UL/ETL mark + GFCI protection (sniff test: certified units auto-shut off if water touches the motor).

- Wand Ratings: Check if PSI/GPM exceedances void certification. Example: A 3,000 PSI wand should not be used on 1,500 PSI machines.

- Chemical Compatibility: Verify ANSI Z358.1 compliance if using acids/caustics. Non-certified systems risk uncontrolled runoff that strips coatings.

When in doubt, demand the manufacturer's test report, not just a logo sticker. Reputable brands like AR Blue Clean publish full compliance certificates online, including noise decibel logs and pressure relief valve specs. This transparency is your best defense against "certification theater".

Final Thoughts: Safety as Finish Preservation

Pressure washer safety certifications are not bureaucratic hurdles, they are your invisible shield against $500 rework jobs. For a complete field checklist, use our pressure washer safety guidelines. Every ANSI mark and OSHA compliance point exists to protect what matters most: your surfaces. Remember that wagon owner's streak-free finish? It was not luck. It was chemistry-forward preparation, certified nozzle control, and disciplined runoff management.

Do not chase raw power. Chase certified precision. When you respect the standards, your paint stays glossier, your trims stay darker, and your neighbors stay quiet. For deeper technical validation of household pressure washer certifications, consult the ANSI/ISEA Z358.1-2014 compliance toolkit, it breaks down flow rates and activation mechanics in plain language. Your finishes will thank you.