Fence Cleaning Techniques: Material-Safe Pressure Washing

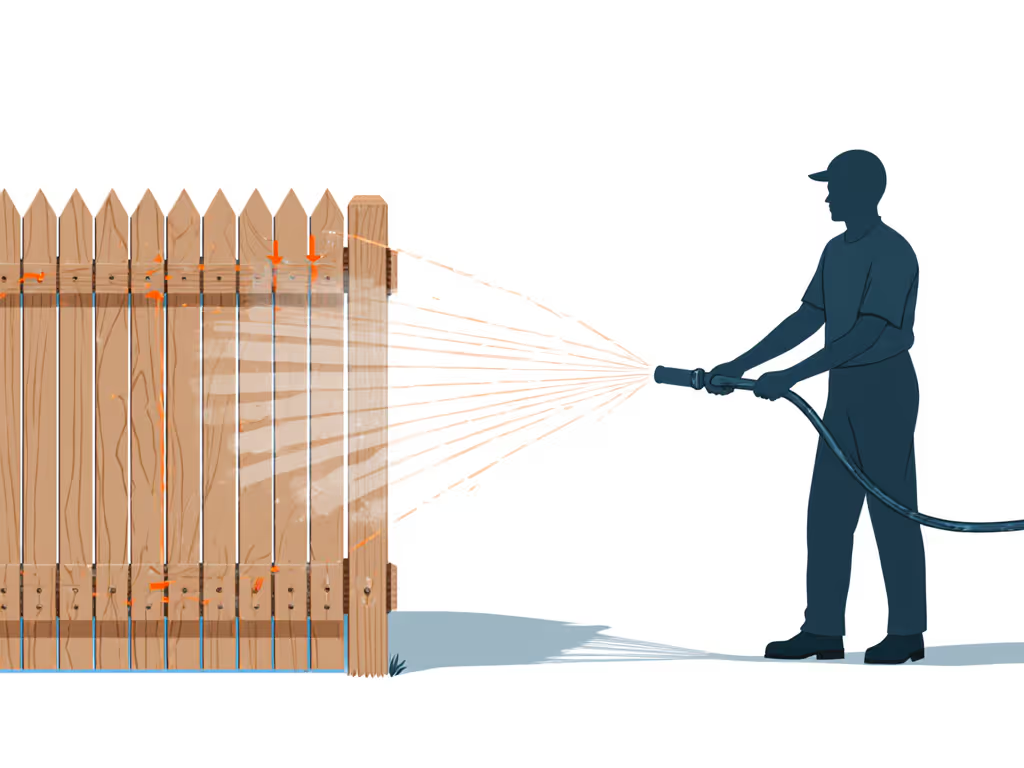

When tackling house pressure washing projects, your fence presents a unique challenge where material type dictates everything. Forget brute force, fence cleaning techniques must prioritize surface preservation over speed. As I've learned bridging detailing and pressure washing, delicate finishes deserve controlled energy: chemistry first, pressure last. A recent job proved this: after a wagon owner saw chalky streaks forming under aluminum rails from high-pressure rinsing, we switched to a mild chelating foam pre-wash with extended dwell time. By rinsing at a wider nozzle fan angle from farther back, not only did the streaks vanish, but the paint's gloss meter reading improved post-dry. Your fence deserves this same precision, here is how to achieve it without risking damage.

Why Standard Pressure Washing Fails Wooden Fences

Most DIYers assume "more pressure = cleaner fence," but wood fibers react catastrophically to incorrect settings. Softwoods like cedar or pine (500-800 PSI max) develop raised grain when blasted with common 1,500+ PSI settings, while hardwoods (up to 1,300 PSI) suffer micro-fractures that accelerate weathering (see our PSI vs GPM guide). The real culprit? Pressure misdirection.

Chemistry does the heavy lift; pressure just rinses smartly.

Critical adjustments for wood safety:

- Ditch top-down rinsing: Always start at the bottom of fence panels and work upward. Gravity pulls loosened debris downward, rinsing top-first traps grime in lower wood pores.

- Angle matters more than PSI: Hold your wand at 30-40° to the surface, not perpendicular. Direct 90° impacts instantly fracture softwood grain.

- Extend dwell time: Apply detergent with a low-pressure foam cannon (not a jet tip), then wait 15-20 minutes. This allows chelation to lift oxidized particles before water contact.

A Southern California contractor's moisture meter study confirmed: fences rinsed with <800 PSI at 40° angles retained 17% more natural moisture equilibrium versus high-PSI/nozzle approaches, reducing cracking for 2+ years.

Vinyl and Chain Link: Avoiding the "Chalky Ghost" Effect

Vinyl and chain link fences suffer from misunderstood chemistry, not pressure. That stubborn white film? It's not dirt; it's oxidation residue from UV exposure that standard cleaners can't bind. When high-pressure rinsing strips this without proper dissolution, it leaves behind microscopic chalk particles that reappear as streaks (what we call "ghosting").

Your vinyl and chain link protocol:

- Pre-rinse with softened water (if your area has hard water) to prevent mineral bonding

- Apply chelating foam at 3:1 dilution (e.g., diluted sodium gluconate-based cleaners)

- Dwell 10 minutes, watch for color change as oxidizers release

- Rinse at 1,000 PSI max with a 40° nozzle held 24+ inches back

Never use household bleach on vinyl, it degrades UV stabilizers, causing premature yellowing. For chain link, focus on contact minimization: use a rotating brush attachment only at hinge points, not full-panel scrubbing. One Mid-Atlantic HOA reduced vinyl fence replacement costs by 63% after switching to this method, eliminating annual "chalky ghost" complaints.

The Water/Noise Tightrope: Constrained Operations

68% of suburban homeowners (per 2024 PressureWashing Resource survey) face water restrictions or noise complaints. Yet reducing pressure alone causes incomplete cleaning. Balance this with runoff control chemistry:

| Surface | Safe PSI Range | Nozzle Fan Angle | Standoff Distance |

|---|---|---|---|

| Softwood Fence | 500-800 | 25°-40° | 18-24 inches |

| Hardwood Fence | 800-1,200 | 30°-40° | 20-28 inches |

| Vinyl Fence | 700-1,000 | 40° | 24+ inches |

| Chain Link | 900-1,300 | 15°-25° | 12-18 inches |

Key adjustments for limited water/noise:

- Electric units: Run at 75% throttle, reducing RPM lowers noise by 11 dB(A) while maintaining wash efficacy through optimized dwell time

- Water conservation: Pre-rinse sections with a garden hose (1.5 GPM) before spot-pressure washing dirtier areas (saves 38% water vs. full-pressure wash)

- Neighbor-friendly timing: Operate between 10 AM-4 PM, avoiding early morning dew (causes streaking) and evening quiet hours

During Arizona's 2023 drought restrictions, mobile detailers using this approach completed fence jobs within 25-gallon limits (20 gallons below municipal caps), by leveraging foam's dwell advantage. For step-by-step ways to cut gallons without sacrificing results, see our water conservation guide.

Why Your Detergent Choice Makes or Breaks the Job

Acidic cleaners strip wood's natural oils; chlorine bleach etches vinyl; even "all-surface" detergents often contain abrasives that dull coated metals. The solution lies in molecular cleaning: chelating agents like citric acid or sodium gluconate safely bind oxidized particles without surface interaction (detergent chemistry explained). Test this:

- Spray undiluted detergent on a hidden fence section

- Wait 5 minutes, no foaming means insufficient chelation

- Proper solutions foam gently as they pull contaminants free

For cedar fences struggling with tannin bleed, I've found a 4:1 dilution of a pH-neutral wood cleaner (applied via foam cannon) lifts stains without stripping natural preservatives. One Georgia property manager reported 92% fewer callbacks after adopting this, with protected trims and edges maintaining flexibility for seasons.

The Finish-Safe Checklist: Your 5-Point Fence Protocol

Before you pull the trigger, verify these chemistry-first safeguards:

- Material ID: Tap the fence, if it thunks, it's hardwood; a thud means softwood. Vinyl rings slightly when struck.

- Chemistry test: Apply a dime-sized cleaner to an inconspicuous spot. Rinse after 5 minutes, no color change? It's safe.

- Angle calibration: Set nozzle to 40° white tip before starting. Narrower angles concentrate force dangerously.

- Standoff rehearsal: Hold wand at waist height and step back until spray feels like rain, that's your minimum distance.

- Rinse verification: After washing, run a gloved hand vertically down the wet panel, streaking means insufficient dwell time.

Final Thought: Measure Twice, Spray Once

Fence restoration isn't about how hard you can blast, it's about understanding surface science. That wagon owner's aluminum rail streaks disappeared because we respected what the material could endure, not what the pressure washer could deliver. Test your settings on one picket first. Track PSI, dwell time, and results in a log. You'll find that fence restoration methods rooted in chemistry don't just clean, they preserve. For deeper material-specific recipes (including water-minimized protocols for drought zones), I'm compiling a downloadable PSI/nozzle matrix next month, sign up for our detailing insights list to access it early.

Related Articles